Products

Cementitious Waterproofing

| Name | Super Blockade | |||||||||||||||||||||||||||||||

| Type | One Component Cementitious Waterproof Coating For Concrete and Masonry | |||||||||||||||||||||||||||||||

| Application Method | Brush applied. | |||||||||||||||||||||||||||||||

| Product Overview |  Super Blockade is a proprietary formulation of portland cements, graded aggregates and chemical additives. The correct amount of co-polymer powder is pre-mixed in the bag, so only water is required to achieve consistent waterproofing of portland cement surfaces. Super Blockade is a proprietary formulation of portland cements, graded aggregates and chemical additives. The correct amount of co-polymer powder is pre-mixed in the bag, so only water is required to achieve consistent waterproofing of portland cement surfaces. | |||||||||||||||||||||||||||||||

| Benefits |

| |||||||||||||||||||||||||||||||

| Placement | Super Blockade may be applied above or below grade. Two coats are recommended for the positive (source of moisture) side, or two coats or more for the negative side. | |||||||||||||||||||||||||||||||

| Substrates | It is effective on plaster brown coat, concrete block, poured-in-place concrete, precast concrete, tilt-up walls, brick and stone. | |||||||||||||||||||||||||||||||

| Examples of Use | Recommended uses include protecting cement plastered walls, concrete foundations, block walls, reservoirs, tunnels, bridges, water tanks, brick structures, and any other concrete, cement or masonry surface subject to damage from moisture. | |||||||||||||||||||||||||||||||

| Components and Storage | Available in 50 lb. (22.68 kg.) pails or bags, in white or gray. Super Blockade must be kept in dry storage area. Shelf life is one year if properly stored. | |||||||||||||||||||||||||||||||

| Coverage | Varies with surface porosity, texture and application thickness. At 1/16 inch (1 .5mm) thickness, 2 Ibs. (0.9 kg.) covers approximately 1 sq. yd .(0.84 m2); 50 lb. (22 .25 kg.) bag covers approximately 200 sq. ft.(18.4 m2). | |||||||||||||||||||||||||||||||

| Surface Preparation | All receiving surfaces must be structurally sound, clean, free of dust, dirt, silicones, paint products, efflorescence or any other contaminant which could hinder bonding ability. Allow new cement and masonry surfaces to fully cure (approximately 28 days) prior to application. Surface cracks, holes or voids should be repaired. Smooth or painted surfaces must be cleaned in an abrasive manner (high pressure water blast, scraping, sanding or sandblasting) to open surface pores and allow for a good bond. | |||||||||||||||||||||||||||||||

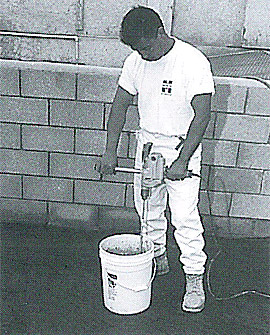

| Mixing | Approximately 1.5 to 2 gallons (5.5 to 7.5 Itr) of clean, potable water are required for each 50 lb. (22.25 kg) bag of Super Blockade. It must be mechanically mixed at a slow speed to produce a smooth workable consistency. Pour about half the required water into a clean container and begin slow speed mixing while slowly adding Super Blockade. Gradually add more Super Blockade and water and bring the mixture to the consistency of heavy pancake batter. Do not over air entrain with excessive mixer speed. Stop mixing and allow mixed material to stand (fatten) for 10 minutes and then finish mixing (re-temper). If necessary, add more water to achieve a brushing consistency. | |||||||||||||||||||||||||||||||

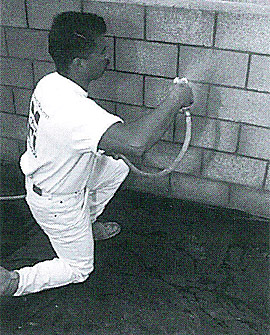

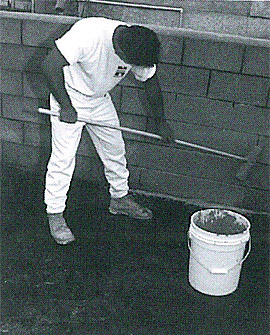

| Application | Evenly wet substrate with clean water to control suction. Apply with 6" (15 cm) masonry brush or 10" (25 cm) tampico bristle push broom. Apply a heavy coat using long, straight horizontal brush strokes in one direction only. Fill all pores and voids. Distribute evenly and avoid excessive build-ups. For maximum protection, allow 12 to 24 hours and apply a second coat. | |||||||||||||||||||||||||||||||

| Clean Up | Water and detergent. Clean spills and spatters before Super Blockade dries. | |||||||||||||||||||||||||||||||

| Limitations | Do not apply over frozen or frost filled surfaces. Do not use when ambient temperature will fall below 40° F (4° C) within 48 hours after application. Do not apply to traffic bearing surfaces. Allow Super Blockade to cure for at least 7 days before filling spas, pools and tanks. | |||||||||||||||||||||||||||||||

| Warranty | Super Blockade Cementitious Waterproofing is warranted to perform in accordance with the product specification when used according to application instructions on the label. This warranty is limited to and shall not exceed the total amount paid by the buyer for the product. In no event will Merlex Stucco, Inc. be liable for loss of profits, special or consequential damages in respect to any claim. The foregoing warranties are in lieu of all other warranties express or implied including those concerning fitness for a particular use. | |||||||||||||||||||||||||||||||

| Environmental & Safety | Super Blockade contains portland cement and is alkaline on contact with water. May be irritating to eyes and skin. Wear appropriate dust, skin, and eye protection. In case of eye contact, flush immediately with water, consult a physician. Wash hands with soap and water after use and before eating. Keep out of reach of children. | |||||||||||||||||||||||||||||||

| Technical Data | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

Mechanical mix at slow speed. |  Moisten substrate with clean water. |

Apply with long horizontal strokes. |  Brush in one direction only. |

Contact Merlex to learn more about concrete and stucco walls.